Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Wisconsin Metal Tech’s leadership set an ambitious goal to double the company’s revenue without adding administrative staff. The greatest obstacle was the company’s aging Shoptech E2 system, which couldn’t support the company’s complex processes and made it necessary for employees to rely on spreadsheets, printouts, and workarounds. With minimal in-house IT staff, Wisconsin Metal Tech began looking for a cloud ERP system that offered robust manufacturing capabilities.

At A Glance

We can now check the current status of any job out on the floor, see exactly what we’ve got in inventory, monitor who’s on which machine, and access records from any workstation in the company. Rather than wasting our time digging through paperwork, we can find answers and make changes to the production schedule on screen in seconds. Even after a year on the system, we’re still finding better and better ways to increase our efficiency with Plex.

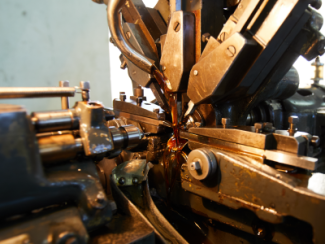

Some manufacturers strive to be the leading vendor for companies in a particular industry. Wisconsin Metal Tech aims to be the go-to CNC machining partner for any company that needs a single-source manufacturer. Based on its ability to source materials, design parts, and build to specifications, the company has attracted clients from industries as diverse as aviation and food service.

“Our customers come to us because we provide excellent customer service and are willing to work with them on lead time, pricing, and expediting orders,” says Laura Luft, Materials and IT Manager, Wisconsin Metal Tech. “They don’t have to go to three different vendors because we can take care of everything under one roof. If it’s a complex job that other manufacturers don’t want to touch—that’s where we really shine.”

Until recently, Wisconsin Metal Tech ran its business on the Shoptech E2 system. But the company found itself relying on various workarounds that involved printouts, pen-and-paper work, and manual data entry. Quality management varied from one department to the next, often revolving around spreadsheets and handwritten documents. It was nearly impossible to track materials and inventory—and data analysis was a chore. These challenges were standing in the way of daily operations and the company’s growth plans.

“Nearly our entire team had issues with our E2 system,” recalls Luft. “Our president was frustrated with how simplistic the financials were, so we needed something with stronger business operations capabilities.” More importantly, our owner had his sights on doubling the size of the business and perhaps considering future acquisitions—all without adding administrative headcount. He saw our Shoptech system as an obstacle to that goal.”

Strong Partnership and Executive Engagement Drive a Successful Go-Live

As Wisconsin Metal Tech began searching for a new solution, the company assembled an internal team of subject matter experts to represent the broad needs of the business. The manufacturer also brought in a consulting partner for advice on the search, and he quickly encouraged Wisconsin Metal Tech to take its operations to the cloud.

“We knew we needed a more robust solution, which would require a more powerful server,” says Luft. “But we don’t have someone in-house to maintain hardware. It made sense to consider a cloud solution.”

Following a Plex Smart Manufacturing Platform demo, Wisconsin Metal Tech’s leaders were impressed by its comprehensive approach to managing the plant floor and the business. Plex’s integrated document control system, quality capabilities, error-proofing, traceability functionality and overall ease of use beat out other systems the team considered. With its decision now made, Wisconsin Metal Tech turned to Plex partner Control+M to ensure its implementation was a success.

Headquartered in Green Bay, Wisconsin, Control+M focuses on Plex implementations and optimizations. During the seven-month engagement, Control+M provided Wisconsin Metal Tech with implementation services, data conversion services, and training on the Plex platform.

“Our partners at Control+M went module by module in the Plex platform, walking us through the possibilities and backing everything up with real-life examples,” says Luft. “Our dedicated Control+M consultant really got to know our business processes as if he were an employee. He pushed us to rethink the way we do things so that we could not only get the most out of Plex but also dramatically increase our efficiency.”

What were the keys to a successful go-live? Control+M credits Wisconsin Metal Tech for having the right attitude from day one.

“The kickoff experience with Wisconsin Metal Tech was unbelievably great for a few reasons,” recalls Kevin Poppe, Business Process Engineer at Control+M Solutions, LLC. “They had the right core team assembled, with a fully engaged executive leadership team. Everyone around the table seemed comfortable speaking candidly with us about what would work or not work. As a result, we all managed to stay on the same page from start to finish.”

Powerful Features Boost Product Quality by Preventing Mistakes

As soon as Wisconsin Metal Tech went live on Plex, its dayto- day operations changed dramatically. Rather than having to walk to one physical location to get printed work schedules, shop floor workers can now pull schedules up on a tablet—and see changes in real time. All of the information that used to be in a printed packet along with a work order is now available on screen, linked with the appropriate part number. Not only can shop floor workers change direction quickly, but the company has dramatically reduced paperwork. In addition, having centralized information in Plex has helped streamline the setup process for all of the company’s production jobs because tool kitting can now happen ahead of time.

Plex has also helped Wisconsin Metal Tech boost its product quality. In the past, an operator could run an operation out of sequence or mix up heat numbers during production. Today, the Plex control panel prevents these mistakes by limiting options. In addition, Plex enforces controls around tolerance limits on the company’s check sheets.

“If an operator types in a wrong measurement for a part, Plex recognizes it right away and forces a reconciliation,” explains Keith Gruber, Manufacturing Manager, Wisconsin Metal Tech. “A lot of these checks and balances were not in place before. And when a mistake is made, it’s now much easier to find the root of a problem and document scrapped materials, which is saving us several hours of paperwork per week. Plex also has a feature where we can see how the entire plant is performing in terms of quality, right at our fingertips. That’s a huge plus.”

The time savings at Wisconsin Metal Tech extend beyond the shop floor. Plex is helping support the company’s growth goals without adding administrative headcount. It used to take the company an hour to enter a complicated part into its previous system, print out all of the related paperwork, and start a job for it. With Plex, it takes just seconds.

“Areas such as accounts receivable and customer billing are so much more efficient with Plex,” says Kristen Lorrigan, Sales Coordinator, Wisconsin Metal Tech. “I’d estimate there’s a 40 to 50 percent time savings in accounting—which frees up staff to help out with activities such as quoting, which will help us land new business. If we hadn’t switched to Plex, we almost certainly would have had to add another member to our office staff by now.”

Real-Time Visibility Helps Growing Company Remain Agile

As Wisconsin Metal Tech competes for new accounts and grows its client base, the company will need to remain agile to changes in the market. With a cloud-based solution in place, the COVID pandemic tested that agility and Wisconsin Metal Tech passed with flying colors.

Plex delivered real-time visibility into all aspects of its operations and did so in a way where all information was available to any employee, from anywhere, enabling the company to adjust to COVID and other market disruptions.

“We can now check the current status of any job out on the floor, see exactly what we’ve got in inventory, monitor who’s on which machine, and access records from any workstation in the company,” says Gruber. “Rather than wasting our time digging through paperwork, we can find answers and make changes to the production schedule on screen in seconds. Even after a year on the system, we’re still finding better and better ways to increase our efficiency with Plex.”

About Wisconsin Metal Tech

Wisconsin Metal Tech is a full-service contract CNC metal machining, centerless grinding, and material supply company. The company serves original equipment manufacturers and contract part and assembly providers worldwide. Customers rely on Wisconsin Metal Tech for rod and bar supply, and for value-added secondary services such as sawing, heat treating, plating, or grinding.

Industry: Metalforming

Location: Richfield, WI