Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

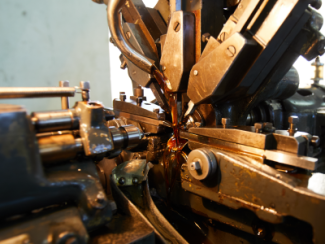

Swoboda manufactures injection molding over electronic circuitry which is used in automotive engines, transmissions and system controls. The company is a leader in the technologically complex area of molding elements.

The U.S. Swoboda facility, located in Grand Rapids, Michigan, produces complex composite parts, such as lead frames for transmission control units and coil systems.

At A Glance

Business Situation

Swoboda’s German headquarters uses SAP as its ERP solution. The U.S. facility, started in 1998, used a variety of solutions and eventually determined it would improve business processes to standardize on a comprehensive ERP solution. After a focused search and evaluation of multiple potential technology solutions, in 2005 Swoboda chose and deployed Plex ERP at its U.S. facility.

Technical Situation

Swoboda’s U.S. facility was faced with a common challenge for a rapidly growing manufacturer: it had adopted specific technology solutions on an ad hoc basis, resulting in a series of incompatible solutions. Eventually the facility had between 30-40 different technology solutions, most of which couldn’t easily communicate with each other or share data. Swoboda required a solution which could address several challenges negatively impacting the operational efficiency of the facility:

- Reduce excessive administrative time managing and coordinating upgrades

- Reduce necessity of technology upgrades

- Create a common reporting tool among systems

- Reduce and/or eliminate work instructions

- Eliminate multiple, sometimes conflicting datasets and have “one version of the truth” throughout the enterprise

Solution

Swoboda decided to better serve its customers by reorganizing into a business unit structure by customer. The Plex Smart Manufacturing Platform helped make this transition smoother and less stressful. The advantage inherent in the business unit structure by customer is a sense of ownership by individuals dedicated to the customer’s account. The business unit is entirely responsible for all facets of the production process for the customer: inventory control, scheduling, quality, reporting and shipping.

Since transitioning to the business unit by customer model, Swoboda has eliminated positions which were once solely focused on one job function: quality, purchasing, shipping and materials positions are now managed by the unit business manager.

This lean approach has allowed Swoboda to convert staff to other more productive positions while still maintaining the quality for which it is known. Now individuals within the business unit have multiple responsibilities for project management, advanced quality planning, product improvement, supplier development and process support. After Swoboda evolved the positions to have broader responsibilities, the workers embraced the change because of the variety and challenge, plus the opportunity to grow professionally by mastering more skills.

Replacing multiple programs with one system translated into easier-to-generate reports for analyzing operational efficiencies. All data is reported with “one version of truth” which provides a consistent, more accurate overview of the manufacturing processes.

Plex helped to automate databases and work processes which resulted in more efficient production. Whenever an existing or new customer introduces a new requirement, the business unit first automates the new process through the Plex Smart Manufacturing Platform. New orders can be managed by existing staff without hiring additional workers.

“With the broader responsibilities needed in our production processes, everyone has the opportunity to contribute, be challenged and grow in the job.”

Since the deployment of Plex at Swoboda:

- Sales have tripled while staff levels have remained stable during the same time period.

- Scrap rates since 2006 have been reduced by more than 50 percent.

- Productivity – measured by sales dollars per labor hour – more than doubled.

- Cycle count adjustments to inventory have been cut by 90 percent.

- Without the reorganization of the business units and adoption of Plex, the increased efficiency and output would not have been possible.

- Work instructions have been reduced by 75 percent because of automated and simplified work processes.

About Swoboda US Inc.

Swoboda is a family owned business that operates around the world with facilities in China, Czech Republic, Germany, Romania and the United States. Swoboda has approximately 1400 employees and develops and manufactures high-precision metal-plastic components for automotive electronics.

Industry: Automotive

Location: Grand Rapids, MI