Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Kendrick Plastics Consolidates 27 Software Systems, Gains Control with Plex

Kendrick implements Plex, a multi-tenant cloud solution, to eliminate disparate software and redeploy people to more valued-added roles.

After being spun off from its previous ownership, Kendrick Plastics needed to scale down from a multi-national manufacturing management system to a middle-market regional system. Utilizing multiple software systems to facilitate manufacturing operations was inefficient and uncompetitive for a business their size. These systems absorbed valuable resources across departments, including manual data reconciliation, significant IT support for hardware and software management, and managing suboptimal manufacturing data tracking. This software environment created data silos, leading to issues with synchronization that resulted in high costs and limitations on their ability to innovate.

At A Glance

With the real-time data we see in Plex, we can identify manufacturing variances and make corrections on them throughout the day. Also, because Plex is so easy to use, people across our organization can access financial data points not available before. This visibility increased the overall financial acumen of our whole business, helping us understand how our day-to-day operations affect our bottom line.

When Kendrick Plastics began the process of spinning off from a larger company, one of the top priorities was to find business systems that scaled appropriately to the newly sized organization. Prior to Kendrick’s formation, this site operated as a plant within a larger organization and used 27 different software systems. Kendrick knew the move to Plex would streamline their operations.

“We view our IT processes through the eyes of a software company that makes car parts. With this mindset, Kendrick is open to reviewing any solution that helps us improve our efficiency while continuing focus on our quality, and productivity,” explains David Chupp, IT Manager, Kendrick Plastics. “Improving our data synchronization was a driving force behind moving to a new system. In addition, our previous applications needed to be routinely updated and maintained. This required time and additional local IT staff which we wanted to avoid. Paying so much attention to our business systems would hinder our ability to innovate.”

With that hindrance in mind, Kendrick set out to consolidate onto one platform. They desired a system that would provide real-time data on manufacturing operations and financial performance. They also wanted a quick-to-implement product that is user friendly and accessible to employees from anywhere. This list of requirements naturally fit with Kendrick’s preference for cloud platforms.

“Our company was born and bred in the cloud,” says Chupp. “Working in the cloud has always enabled us to be agile and reactive to our ever-changing environment. It didn’t take us long to realize that Plex was the right choice for us.”

Business Keeps Running During a Seven-Month Implementation

Despite launching the project in 2020 during the pandemic, Kendrick Plastics went live on Plex in just seven months—but the company didn’t cut any corners. Kendrick spent considerable time verifying the data that would feed into its new platform.

“We preformed multiple tests of EDI connections and labels to ensure the data from our existing systems transferred correctly into Plex,” says Andrew Masterson, Director of Sales and Operations Planning, Kendrick Plastics. “We provided training sessions on all three shifts to ensure there would be adequate support and operators could be productive on the new system from day one.”

As a result of Kendrick’s conscientious approach, the implementation was seamless. In fact, customers couldn’t even tell that the company had switched systems.

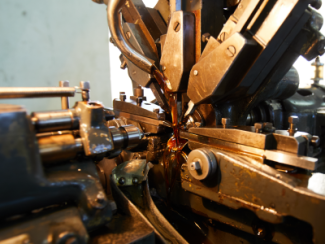

Driving Higher Quality with Machine Connectivity Through PLC Integrations

As soon as Kendrick Plastics went live on Plex, employees began to benefit from a quality control process that provides highly detailed information to minimize the chance of defective parts being shipped to customers.

“Thanks to Plex, we now have a wealth of PLC information for quality control,” explains Chupp. “At a minimum, we do pass/fail checks of parts right at our machines. On the more extreme end, we capture data such as torque, angle, and screw pressure. We tie that information to an individual serial number to give us full traceability throughout the assembly process. We also use fields integration in Plex to make sure our hydro-printed graphics match from the start of the manufacturing process to the end. This helps us prevent easily overlooked problems, such as grains not quite matching up, so we can ensure the best possible product for our customer. When we see a certification that a part is ready to pack, we know we can trust in the quality of that part.”

If a defective part ever does make it to a customer, Plex makes it easy to pinpoint the cause. Kendrick team members simply get an individual piece serial number or Plex container serial number from their customer and go from there.

“With the container number, we can see every individual piece serial number that went into that box,” Chupp continues. “We can review all the quality control transactions that occurred during production and all the raw material that went into the part. From there, we can quarantine the products that use that part and even reach out to customers proactively to get parts back. This process was not as easy before Plex—recalling a part would have required us to pull a far larger lot size, which requires much greater effort and expense.”

Kendrick has also built real-time pace boards that allow the entire team to see Plex production records as they work. Using these visualizations, teams can easily determine whether their machines are running at pace.

“Self-awareness of station pace improved drastically by simply displaying a pace board,” says Ali Thomsen, Plant Manager, Kendrick Plastics. “Due to color-coding, we can all see at a glance if we’re running at our required rate. As supervisors walk around the floor, they have the truth right there in front of them. Our operators now feel empowered to share with their supervisors what adjustments need to be made so that they can get up to their ideal rate of production.”

Detailed Scrap Data Enables Earlier Intervention

Although many manufacturers find that Plex meets their needs right out of the box, Kendrick Plastics saw the potential for further innovation. The company built an application layer on top of the Plex Manufacturing Execution System (MES) to meet its specific business needs.

“Plex provides a ton of APIs that make it incredibly easy to interact with the system,” says Chupp. “We went way beyond just recording production or recording downtime. We can let Plex do all the hard things, such as managing inventory costing or making sure that our bill of materials depletes correctly, while we focus on making better decisions based on the tremendous amount of data the system generates.”

Plex quickly helped Kendrick Plastics improve efficiency and accuracy around its scrap function. Before going live, Kendrick had a full-time employee who spent 40 hours per week entering data on scrap and machine downtime, and there was a 24-hour lag in seeing the previous day’s efficiency metrics. Today, the whole team can see scrap data immediately and without the need of a full-time data entry resource, enabling that person to move to a higher-value job.

Timely reporting is critical to Kendrick’s business. Plex offers pre-packaged analytics tools but also makes the data accessible so customers can use the reporting solution of their choice for custom-tailored needs.

“As soon as operators enter scrap data at their workstations, we can see it in real time,” says Thomsen. “All the data is available on a highly intuitive Power BI dashboard that allows us to view the data in different dimensions. This enables us to react much more quickly in rectifying problems.”

As employees investigate a certain program or process, they can see its scrap data as far back as they want and identify trends. With this visibility, Kendrick Plastics has already significantly reduced its scrap since implementation.

Efficiencies Abound in the Cloud

Kendrick has gained yet another capability with Plex: barcode scanning. The company can now track inventory precisely as plant floor workers scan it into and out of every location in the facility, all of which is captured in Plex in real time. In addition, Kendrick has dramatically streamlined its batch building process. Rather than pre-printing a stack of container labels, the company can simply print them after production based on records in Plex.

Efficiencies abound across Kendrick’s business. Rather than walking over to the raw material bank and waiting for a product to be dispensed, plant floor workers can order it from their workstations and pick it up when it is ready. The company manages EDI connections for 50 customer trading partners and 100 suppliers right in Plex, rather than logging onto a separate system. And the company’s purchase order process has gone from a multi-day challenge to a five-minute approval process.

Kendrick Plastics also appreciates the unique benefits of using a cloud-based ERP system, which includes MES and quality built in. With Plex, the company has a highly reliable system that makes it easy for stakeholders to access financial data anytime, anywhere.

“With the real-time data we see in Plex, we can identify manufacturing variances and make corrections on them throughout the day,” says Amanda Gallagher, Controller, Kendrick Plastics. “Also, because Plex is so easy to use, people across our organization can access financial data points not available before. This visibility increased the overall financial acumen of our whole business, helping us understand how our day-to-day operations affect our bottom line.”

Kendrick Plastics doesn’t plan to stop moving forward anytime soon and knows their Plex system is built to scale with them.

“The biggest advantage of having a cloud ERP system is the uptime and reliability,” concludes Chupp. “With Plex, we know that as long as we have an internet connection, we can keep shipping products. That alone is increasing our competitive advantage.”

About Kendrick Plastics

Kendrick Plastics is a Tier 1 and Tier 2 supplier of interior decorative trim components and assemblies to the automotive industry. Their 300,000 square foot engineering and manufacturing facility has more than 50 presses serving fully automated paint lines and assembly stations. The company is 100% certified for IATF 16949.

Location: Grand Rapids, MI

Founded: 2019