Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

JF Fredericks Aero Watches Supplier Ratings Soar after Implementing Plex Smart Manufacturing Platform

JF Fredericks Aero’s new leadership aimed to restore the company to its leadership position in the aerospace industry by improving customer satisfaction and its supplier scorecards. The manufacturer’s paper-based production planning and scheduling processes weren’t delivering the information JF Fredericks Aero needed to compete. The team immediately focused on implementing a solution that would provide the control and visibility it needed to make more accurate promises to customers—and improve its audit scores.

At A Glance

To me, the biggest benefit with Plex is the ability to grow with existing resources. Once processes are configured and implemented properly, we can easily take on additional work knowing that tasks such as document generation, invoicing, and document control will be automated.

When JF Fredericks Aero’s new leaders arrived in 2017, they were taking over an aerospace manufacturing operation with a rich history. However, the company had slipped from its frontrunner status in recent years. The new team was motivated to restore the company to its once top position in aerospace and capitalize on the industry’s significant growth, but to get there, JF Fredericks Aero needed to boost confidence among longtime customers and drastically improve suffering supplier scorecards.

“Customers continued to buy legacy products from us, but we weren’t getting many new orders,” recalls Jeff Astle, General Manager and COO, JF Fredericks Aero. “With the uptick in the industry, we had a perfect opportunity to revitalize our existing relationships and attract new long-term customers. But we were shooting ourselves in the foot with poor planning, poor processes, and a lack of ability to commit.”

Astle and his team knew that to be able to make realistic promises to customers and scale the business, they would need to start deploying the workforce more strategically, with minimal waste. But JF Fredericks’ antiquated processes and systems stood in the way. The company’s existing enterprise resource planning system was being used as a mere accounting system. Document control and document processing revolved around filing cabinets. Shop floor teams lacked the technology they needed to maximize their efficiency. Production planning was an entirely manual process.

“The master production plan was a printout with a schedule handwritten on it,” Astle explains. “When we would get together for meetings twice a week, one person would have that ‘master’ schedule in his back pocket and nobody else in the room would know that there had been changes to it. It’s no wonder that we had no way of tracking our ability to meet commitments.”

Proven cloud solution meets challenging requirements

As Astle and his colleagues looked to the future, they realized they would need a modern ERP that could provide greater control over the shop floor. JF Fredericks craved tighter document control, real-time inventory information, and powerful production planning and scheduling capabilities—all to support making accurate promise dates to customers. Any new system would also need to provide strong enough security capabilities to satisfy the company’s growing number of military customers. JF Fredericks saw cloud solutions as a viable approach for several reasons.

“The cloud lets us establish data backup and other risk mitigation factors that can help us keep our business running even in the event of massive computer failures,” says Stephen Gabbert, co-owner and CTO, JF Fredericks Aero. “Implementing a cloud solution also means our decision-makers can access the information they need from either our main plant or our sister company, without having to go through a VPN.”

Because Gabbert and Astle had both used Plex at former employers, they knew the system could meet their needs. After seeing presentations from several vendors, JF Fredericks chose to implement the Plex Smart Manufacturing Platform with the help of the Plex Customer Success and Support (CSS) team. The company went live in just four months.

Rebuilding a company by restoring customer confidence

Following implementation, it didn’t take long for the JF Fredericks team to see an impact on the business. One of the first major differences: the quality of customer relationships. To put it simply, customers quickly gained confidence that the vendor was in full control of its manufacturing processes.

“Plex immediately made our customers more confident that we could meet their expectations,” Gabbert recalls. “When they could suddenly see real-time information on our production processes and check up on our revision controls and document controls from one screen, that sent the message that JF Fredericks is rebuilding itself based on outstanding service.”

That confidence extends to JF Fredericks employees. There are now computers or touchscreens at every work center on the plant floor. Rather than consulting a printout, teams can view an accurate production schedule—updated in real time—on a screen.

“Nearly everyone in our organization is using Plex daily,” reports Astle. “The system makes it easy to set priorities. Everyone understands at a glance what their schedule is. And you don’t need to walk out on the shop floor to track inventory—you can just check a status screen to see exactly where materials are and how machines are performing at any moment.”

Having detailed information available on production processes has dramatically streamlined JF Fredericks’ audit process. The company can easily show auditors a full history of who was involved and what happened during any production run.

“Our audits have been outstanding since we put Plex in place,” Gabbert confirms. “Auditors can easily review our entire revision history and see the stringent controls we have in place for user approvals. For part auditing or cycle counts, just being able to see all of our parts in transition so that we know exactly where to find them on the floor is also very helpful.”

By tapping into Plex’s capacity planning and scheduling tools, JF Fredericks is now splitting workloads, shifting operators, and making overtime decisions based on what will best meet customers’ expectations. All of this is enabling the company to provide customers with highly accurate promise dates—and increase customer satisfaction.

Supplier performance ratings go sky-high

JF Fredericks’ biggest goal in upgrading its technology was to enable steady growth without increasing overhead. With Plex, this goal has become a reality. The company has streamlined many routine accounting tasks. Whereas the company’s controller previously had to analyze each job before closing it, jobs are now automatically documented by Plex and costing is built into the system. Now, the controller can focus on more strategic work versus needing to prioritize manual checkpoints.

JF Fredericks has also gained far greater control over its plant floor and engineering processes without adding headcount. When a machine isn’t set up properly or an incorrect material is being used, shop floor staff can easily start the turnback process to get team members to review and fix the error. Teams can also automatically trigger a rework cycle when a part doesn’t conform to behavior standards—and create certifications automatically when it’s time to ship parts.

“We love the quality gatekeeping features in Plex,” says Astle. “If a part has an issue and hasn’t cleared inspection, the system won’t let us ship it. Having this kind of control not only helps us maintain high quality, but also impresses our customers and helps us win additional work.”

These new capabilities are making a difference in JF Fredericks’ bottom line. Since implementing Plex, the company has maintained a 15 percent annual growth rate without adding headcount.

“To me, the biggest benefit with Plex is the ability to grow with existing resources,” says Gabbert. “Once processes are configured and implemented properly, we can easily take on additional work knowing that tasks such as document generation, invoicing, and document control will be automated.”

Before implementing Plex, JF Fredericks’ Supplier Health Assessment score from its largest customer was just 28 out of a possible 60. Six months after going live on Plex, the company had made a 15-point improvement in document and inventory control audit categories. One year after going live, JF Fredericks had met its customer’s standard for on-time delivery quality and pricing—and had achieved a 13-point improvement overall while rapidly approaching its largest customer’s highest performance standard.

Cloud ERP helps business keep moving forward even in a pandemic

Even the COVID-19 pandemic couldn’t drag down the company’s success with Plex. Although many commercial aircraft makers stopped buying parts when most flights were grounded, JF Fredericks found itself doing more business with military clients. When about 25 percent of staff began working from home in the first months of the lockdown, they found they could easily keep up with business by logging on from any web-enabled device.

“If we had still been on our old system when the pandemic hit, we would have had to work with IT contractors to build some sort of VPN so that people could work from home,” explains Astle. “With Plex, making that transition to remote work was seamless for our administrative staff. No matter where our people are located or what the situation in the world may be, we can continue to move our business processes forward in ways that keep our customers happy.”

About JF Fredricks Aero

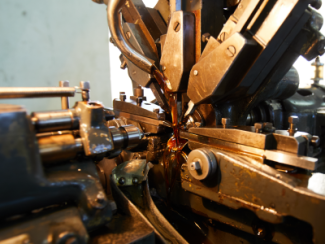

JF Fredericks Aero manufactures aerospace components for major aircraft engine makers such as Pratt & Whitney. The company produces high-temperature, high-precision small components such as brackets, fittings, and housings, made from titanium, Inconel, and other alloys.

Location: Farmington, CT

Founded: 1951