Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

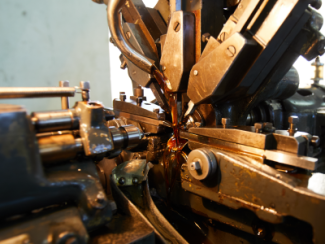

Since its first press started running in the 1960s, metalstamper E&E Manufacturing has prided itself on its ability to engineer and manufacture quality components efficiently and cost-effectively.

The auto supplier invested in its first ERP system, a QAD product, in 2005. Within a few years, the company realized that the on-premise software didn’t include the comprehensive functionality it would need to achieve its planned growth.

Like most ERP tools at the time, the QAD system was focused primarily on financials and didn’t include functions to support operations. For example, it wasn’t able to automate scheduling, track inventory accurately, or minimize the cost of quality. These constraints required E&E to develop and rely on additional homegrown databases, internal systems and manual spreadsheets to supplement its ERP.

At A Glance

"The Plex Smart Manufacturing Platform just turned out to be a more affordable, efficient, comprehensive solution than any of the others we looked at.”

The Upgrade/Replace Dilemma

Senior management began to explore options for upgrading or replacing QAD and its other disparate databases and systems, but those plans got put on hold as all manufacturers faced another more pressing challenge: the economic downturn.

E&E stopped upgrading to new releases of its existing QAD on-premise system during the downturn. It didn’t want to devote the expenses, time or human resources needed to manage the required customizations.

The metalstamper also put off server upgrades and purchases, despite the fact that the existing servers were near capacity and E&E’s database was continuing to grow rapidly.

Time for a Change

After the company emerged from the downturn, the game was back on and senior managers focused once more on the “upgrade or replace” dilemma.

They looked first at what it would take to catch up to the latest QAD software version and server capacity requirements. What they learned was disturbing: before they could even begin the costly customizations needed for the new QAD versions, they would have to purchase “customization codes” from QAD – another set of expenses. And the functionality would still not meet the company’s growth needs.

As the projected costs of maintaining its limited legacy system continued to climb with every new question management asked, E&E shifted its focus entirely on the search for a new solution.

A Natural Fit

After reviewing several cloud-delivered and on-premise ERP systems – including a cloud-delivered option from QAD – E&E Manufacturing chose to launch Plex, a cloud solution designed by and for manufacturers. The company implemented the solution at its two facilities in Plymouth, Michigan and Athens, Tennessee in under a year.

“We knew we needed a more comprehensive robust solution, but we didn’t intentionally set out to find one that is cloud-delivered,” said E&E Manufacturing CFO Brian Swanson.

“QAD also offered us a cloud-delivered system,” Swanson noted. “It appeared to be almost identical to its on-premise solution except we’d be renting the servers from QAD. Plex is totally different. It’s clear from how it operates that Plex is a true cloud model and was developed to optimize the benefits of cloud delivery.”

$50,000 Annual Cost Savings

Plex’s upfront cost for implementation was lower than what E&E would have paid for QAD or any of the other solutions it considered. Also, while QAD’s cloud solution would have required additional annual fees in addition to monthly subscription costs, Plex doesn’t require an annual fee.

“In total, we are saving $50,000 a year in systems costs with Plex.”

“That savings includes not just the flat cost of Plex over our previous ERP solution but also its replacement of the six or seven systems and databases we’d been using for functions ranging from HR to Engineering to preventive maintenance,” said Swanson.

Accurate Scheduling and Inventory Tracking

With Plex, E&E’s scheduling is more accurate and timely. Improved scheduling, in turn, drives better communication between the plant floor, billing and maintenance.

Plex’s traceability functions have also enabled the company to tighten up inventory management.

“We can track every packaged container in each lot, and that’s greatly improved the accuracy of our inventory tracking,” explained Swanson. “Before Plex, we usually needed to adjust our annual inventory by about $70,000. Now our adjustments are negligible – around $15,000 or less.

Cost of Quality Cut Nearly in Half

Today on the E&E plant floor, Plex-generated quality checksheets must be completed before any job is run. The system randomizes the details on the checksheets, ensuring they are carefully reviewed for each job.

For each operation, if the associated checksheet isn’t completed, the machine stops production. The checksheets require supervisor sign-offs. If something is out of spec, the supervisor won’t sign off on the part, and this prevents any quality issues or production delays.

Before, with manual operator checksheets and a manual process, it was hard to catch quality issues until the problems had grown.

Plex’s checksheets and other controls on the plant floor have enabled E&E to reduce its scrap, rework, delays and other factors that contribute to the cost of quality. The measurable results are impressive.

Within just the first year of launching Plex, the company reduced its Cost of Quality (CoQ) by 42 percent.

Supporting a Culture of Accountability

While E&E’s previous system was managed on a pay-per-user basis, Plex supports an unlimited number of users. Not only does this encourage all 400 employees to actively use the system but it puts knowledge into the hands of many people who had not had direct access to operational data before. Management sees this as another benefit.

Explained Swanson, “We’ve always managed our company on the principles of shared communication and accountability, and Plex fosters this across our entire workforce.”

Looking Ahead

What is the biggest benefit of the Plex Smart Manufacturing Platform?

According to E&E, it’s the fact that the solution is rooted in manufacturing.

“Plex understands our business. It was designed by a metalformer with manufacturing needs in mind so it is ideal for any manufacturer. It incorporates all the critical aspects of our businesses and it ties all of them together.”

“Plex has made such a dramatic change in our business,” he concluded. “It may seem strange to think that one system has been able to transform how we communicate and operate here at E&E, but that’s exactly what Plex has done."

About E&E Manufacturing

For 50 years, E&E has served its world-class customers by manufacturing heavy gage stamped metal fasteners, progressive die metal stampings, and high value added assemblies. Their wealth of talent and depth of experience, combined with spotless, state-of-the-art facilities, allow E&E to tackle complex manufacturing problems for customers, which include Tier 1, Tier 2, and OEM clients in automotive, heavy truck, military and other industries.

Industry: Metalstamping

Location: Plymouth, MI