Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

For more than a decade, Batesville Tool & Die had used multiple data systems to manage its various business and manufacturing processes. These custom applications barely communicated with each other—and they couldn’t integrate the company’s plant in Mexico. Batesville sought a leaner, more efficient operation that could help it keep pace with today’s data-driven business environment.

At A Glance

“Plex’s biggest strength is its ability to integrate our manufacturing plants within and across our plants in the United States and Mexico. We are considerably more efficient after integrating PLCs, allowing our operators to function with less manual interaction.”

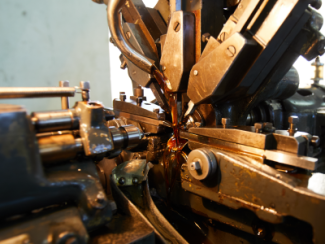

With facilities in Batesville, Indiana, and Queretaro, Mexico, Batesville Tool & Die is a global supplier of precision metal stamping components for automotive, appliance, and other industries. For more than 30 years, Batesville Tool & Die has produced complex stampings and welded assemblies, with stamping capabilities ranging from 50 to 1,200 tons.

For more than a decade, the company had multiple data systems to manage various business and manufacturing processes that barely communicated with each other. Interested in a more efficient and leaner operation in today’s data-driven business environment, Batesville Tool & Die turned to Plex for an integrated enterprise resource planning (ERP) solution. Plex Manufacturing ERP is a cloud ERP solution built specifically for the manufacturing enterprise.

Programmable Logic Controllers (PLC) Integration

Prior to using Plex Cloud ERP, Batesville’s machine presses were integrated using custom software. Although the software was effective, it lacked the ability to expand into other locations, including the company’s Mexico plant.

Plex Systems’ partner Kors Engineering integrated the shop floor PLCs with Plex, enabling seamless, real-time communication. In addition to the consistent interface for operators, Plex also has allowed for a more efficient manufacturing process by automating many functions, including label printing when containers are full. What’s more, Plex has made the monitoring and interaction between plants in Indiana and Mexico more efficient.

Control Plans and Checksheets Augment Shop-Floor Process Efficiency

Plex Cloud ERP provides control plans, which have become an integral part of production as they track the activities on the shop floor. At Batesville’s plants, control plans track the engineering quality of parts and provide consistent and timely communication to operators regarding specifications, setup, and operation instruction to manage the processes with minimum errors to produce good quality product.

Plex has made it easier for the operators at Batesville to enter data into the onscreen checksheets that are fully integrated with, and driven from, control plans. Now, inspection data is fed directly into easy-to-use checksheets, validated against the specifications limits, and stored in the Plex database for the consistent management of the manufacturing process. This data is accessible anywhere, anytime, ensuring efficiency in the process. The checksheets also support pictures and drawings, color-coding, and other features to make them even more effective.

Supplier Assists in Efficient Working

According to Wintz, one of the reasons Batesville chose Plex Manufacturing Cloud ERP was its ability to transcend language and cultural barriers, making it easy to implement and use in multiple locations. Users not only can take advantage of the capabilities but also customize their screens. Plex’s patented interface, VisionPlex, allows users to control the look and usability of their systems. They can dynamically customize screens, design new screens, and link screens together. It’s revolutionary because it eliminates the costly step of software programming.

With Plex, users don’t need to be fluent in software programming or query language. It is intuitive and user-friendly. For instance, any authorized Plex user can create a custom menu that reflects his or her daily tasks. At Batesville, users have customized their screens and functions to meet and highlight specific needs, improving work efficiencies and performances. For example, most of the efficiency reports are customized on VisionPlex screens for easy and quick viewing.

“Customized screens, menus, and reports have become more important to us and we are using them more and more,” explained Wintz.

Plex has automated processes and increased efficiencies for Batesville. It has enabled the company to integrate all of its administrative, engineering, production, and manufacturing processes.

“We went into Plex Cloud ERP with a little bit of apprehension about its reliability. We are pleasantly surprised and extremely satisfied with the security and reliability of the cloud ERP solution,” said Wintz. “We have improved our process efficiencies to a great extent."

About Batesville Tool & Die

Batesville Tool & Die is a global supplier of precision metal stamping components for the automotive, appliance, industrial, and other industries. The company operates ISO/TS-certified facilities in Batesville, Indiana and Queretaro, Mexico. As a full-service supplier, Batesville has a wide range of capabilities, including metal stamping, welding, and assembly.

Location: Batesville, IN

Founded: 1978