Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

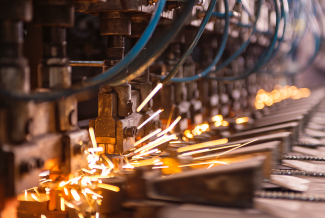

Asset Performance Management (APM)

Proactively monitor machine and plant health to ensure optimal uptime, throughput, and maintenance needs.

Leverage the benefits of analytics and Industrial IoT technology to gain deeper insight into plant-floor equipment and enable predictive maintenance.

Monitor machine health

to reduce production disruption due to surprise outages and machine failures

Drive predictive maintenance

to decrease the time it takes to diagnose machine health events and improve historical data traceability

Contextualize IT/OT data

in a single view to connect plant floor data with MES data and support informed decision making

Plex Asset Performance Management (APM)

-

Maximize Uptime

Eliminate unplanned downtime and hit your production targets

Use real-time data collection and built-in analytics to capture and analyze live data on machine health and performance, compare machines against a desired state, and generate early notifications of potential disruption to reduce overtime labor, scrap, emergency maintenance costs and over P&L impacts.

-

Reduce Machine Failure

Improve your ability to identify and prevent machine health incidents

Visualize and trend analytics to support accurate and timely diagnosis of failure causing conditions using historical data storage. Contextualize machine activity with details on specific operations to drive predictive maintenance using contextual traceability.

-

Consolidate Data Silos

Manage all your data in one system to create context and connected workflows

Contextualize a combination of OT data from the plant floor and IT data from Plex MES to create single view and support informed accurate decisions. Create and manage maintenance requests in MES or CMMS system directly from Plex APM for more efficient management of asset performance.

Aligned with extreme precision to the pillars of Smart Manufacturing.

Plex Asset Performance Management (APM) is designed to provide immediate value for your company, while preparing you for whatever tomorrow brings.

What is Smart Manufacturing?-

Connect

Connect shop floor performance data to maximize production and operational visibility.

Image

-

Automate

Automate alerts sent to personnel who can effectively react to behavioral data that’s outside of the norm.

Image

-

Track

Track equipment performance trends over time to predict downtime for proactive planning.

Image

-

Analyze

Analyze trends and compare operational data against other KPIs to discover new opportunities for improvement.

Image

Plex Asset Performance Management (APM) Features

-

Image

Real-time visibility

Using real-time sensor inputs, machine states, PLC events, error codes, and part numbers, Plex APM will generate live views of what’s going on in your manufacturing environment.

Image

Contextual traceability

Consolidate disparate silos of data into one system to gain a contextualized view as to why machines are not performing to the best of their ability and what was impacted when an issue occurs.

Image

Preventative data and trends

Historical data storage and trend analytics allow for the support of accurate predictive maintenance and diagnosis of failure causing conditions.

Image

Built-in analytics

Use a variety of custom rules and analytics to ensure machines are running as desired and generate notifications against potential machine failure to guide corrective action.

"Plex has simplified data gathering and data management at all levels of our enterprise, allowing savings in time and resources."

Arvel Wooten

Organizational Development Specialist, Hatch Stamping

See Case Study

“Using IIoT technology, Plex Asset Performance Management will provide us a direct view into the status and overall performance of assets; what we really get excited about is the ability to tie quality and part level performance expectations to asset performance – information that has traditionally been extremely difficult to generate.”

Bob Bierwagen

VP of Digital Strategy, MPI Corporation

Learn More