Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Subscribe to Our Blog

For a monthly digest of expert insights, data points, and tips like the ones in this article.

The Top 3 Challenges Facing Manufacturers (and How to Solve Them)

State of Smart Manufacturing, Smart ManufacturingEach year, the State of Smart Manufacturing Report compiles feedback from hundreds of manufacturers. For nearly a decade, these findings have shown supply chain disruption, skilled worker shortage, and security/risk management as top challenges for business and the pandemic has made this worse.

To build a business fit for resiliency, manufacturers must identify these pain points in the light, assess the degree of severity, and determine how best to solve these problems. With smart manufacturing in place, organizations can prevent, address, and solve major business challenges and growth obstacles, including unexpected complications and developments.

Challenge #1: Addressing the Skilled Worker Shortage

Companies are addressing the skilled workforce issue by leveraging innovation, technology, and their ability to use data to make decisions. Employers that can equip employees with the right tools while also supporting the path for learning and development will be best positioned for the future.

By implementing technologies that streamline processes and automate less attractive job functions, manufacturers attract workers. That automation creates opportunities for more value-adding work rather than repetitive tasks that can be handled by smart technology.

Challenge #2: Dealing with Supply Chain Shortcomings

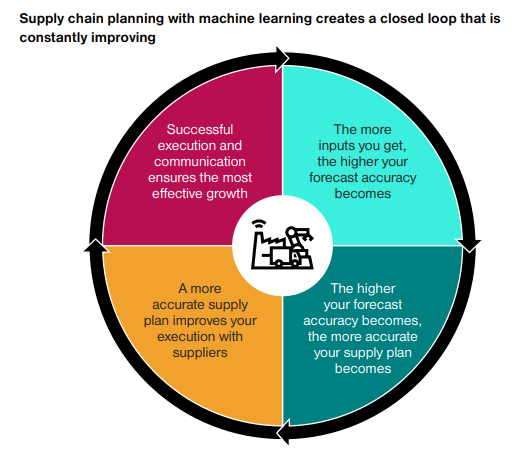

Seventy percent of respondents in the State of Smart Manufacturing Report are using supply chain planning systems that rely on spreadsheets and manual processes. However, that won’t be enough going forward. No matter how sophisticated these types of solutions might be, they cannot handle the level of computation that a dedicated supply chain technology tied to machine learning can.

Supply chain planning specific solutions pull in data from multiple sources in real time to provide the most accurate information possible. This will help manufacturers better meet changing needs and keep pace with supply chain nuances, from the cost of materials coming in to reforecasting and shipping out.

Challenge #3: Mitigating Risk and Improving Security

In the last few weeks of 2021, manufacturers faced unprecedented levels of ransomware attacks. Though some larger companies publicly disclose these attacks, many more go unreported at smaller organizations. Small companies often bear more risk because they may not be able to afford to pay ransoms. Every organization should be vigilant and have a proactive security plan to avoid or minimize risks of attacks.

Often, the role of security and risk mitigation falls on information technology professionals, but IT roles are among the hardest to fill globally. By using a multi-tenant cloud SaaS solution, you gain a software, hardware, and security support team that is in the business of protecting your company and data — far more professionals and experts monitoring your system than you could independently hire, train, and manage. The advancement of cloud combined with hybrid cloud where data analytics are processed closer to the customer edge further demonstrates the need for flexible cloud applications.

What Can You Do?

The trouble with the skilled worker shortage, supply chain issues, and security/risk mitigation will not suddenly disappear. While there is no quick and easy fix, there are solutions. Best-in-class manufacturers are investing in smart manufacturing to address these ongoing challenges with modern approaches that account for the dynamic complexities these challenges bring. Smart manufacturing enables businesses to adapt to a changing market and unlock long-term opportunities by connecting and automating their operations.